Subpanel Inspection

A subpanel is a secondary electrical panel. It is also called a distribution panel and your home may have multiple, just one, on none at all. Subpanels are used when there is not enough room in the main panel.

Wiring a subpanel is not the same as a main panel. Many times I find subpanels that are wired wrong. But let’s focus on the positives first.

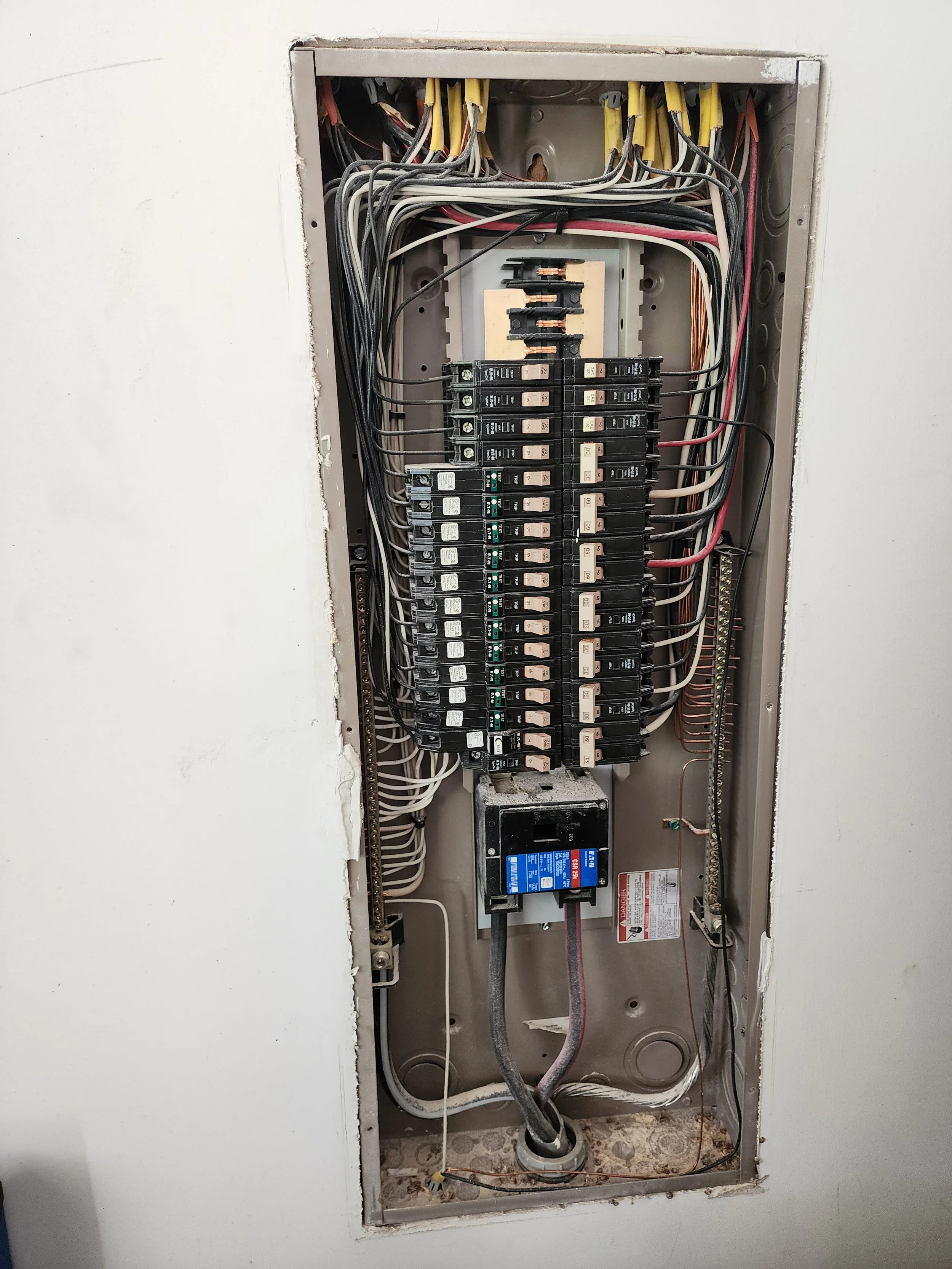

This is a subpanel from a newer home that was wired correctly. Let’s break it down.

There are 4 wires that feed the panel. These wires come from the main panel. In this case the main panel was outside by the electric meter.

1 & 2: The black/red wires bring current into the home. Each supplies 120 volts to the home. Individually either can supply power to lights, outlets, etc., but when combined they provide 240 volts which most larger appliances require (think electric water heaters, dryers, furnaces, etc.).

3: The white or white striped neutral wire receives current from outlets, lights, etc., and takes it back to the main panel, power lines, etc. Electricity needs a circuit to flow properly.

4: The Equipment Grounding Conductor or EGC. This is often a bare (uninsulated) wire but may have green insulation. Here it’s aluminum but it can also be copper. Many people call this a ground but it’s actually a bonding wire, which means it connects non energized metal parts (such as gas lines, metal outlet boxes, etc.) back to the ground wire usually located in the main panel.

Speaking of which, the main panel has the same wires, 1 neutral, 2 hots, and 1 EGC.

The 5th wire you see is the home’s ground wire. It goes into the earth below. In the event of a lightning strike it can redirect current from the home preventing fires and electrocutions. I have a post about this here.

At the main panel the Neutral, EGC, and Ground Wire are bonded (connected). This is important as it creates a grounded system that we rely upon for breakers to trip properly among other things.

But in a subpanel the EGCs and Neutrals are NOT connected. Why? Because in that scenario, the neutrals can put electric current on the EGCs, which are not intended to have current on them except in emergency situations. Anybody working on these wires could suffer a shock hazard because of this.

So we need to make sure the EGCs and neutrals are separated in the subpanel which they are here.

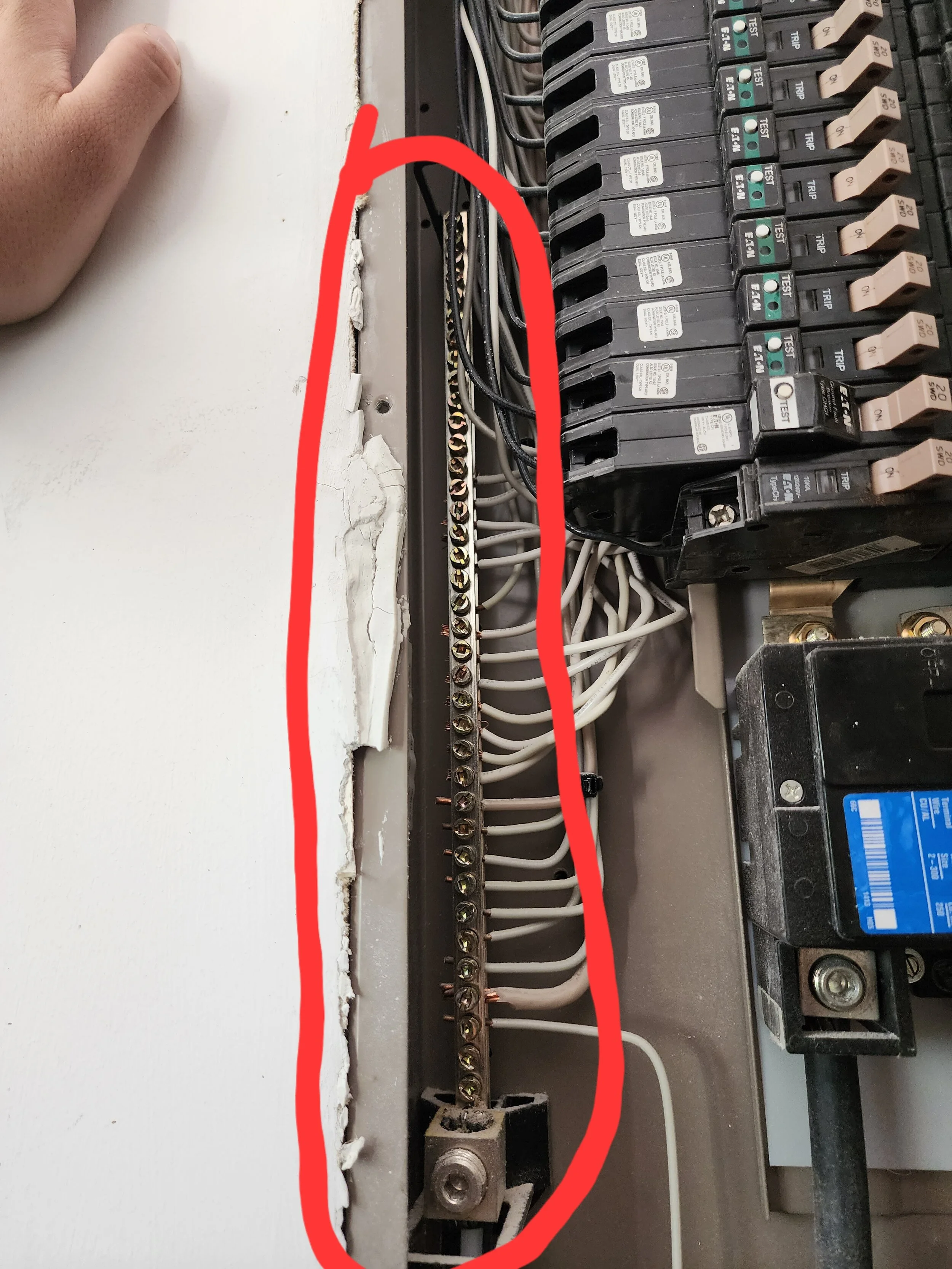

The white wires are terminating on the neutral bus bar here. If you look closely you may notice they are not in contact with the panel. This is correct.

There should only be one wire under each screw. It was common in the past to put two wires under one screw but is a violation and should be corrected.

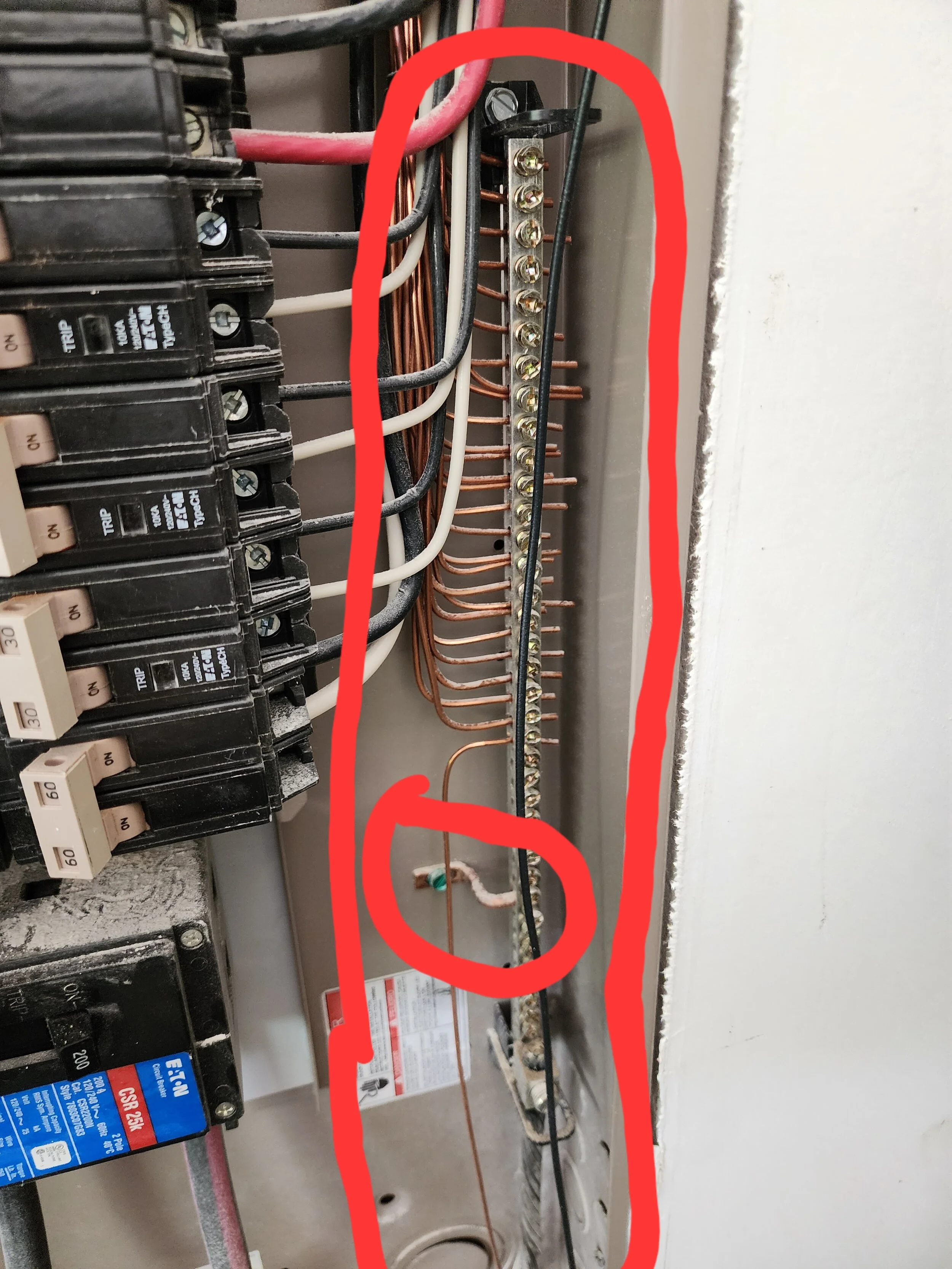

The copper “grounds” or EGC wires are terminating on the opposite bus bar. This bus bar IS connected to the panel via a bonding jumper circled in red. Why? In the event a live wire were to come into contact with the panel, the current would travel through the jumper back along the main EGC to the main panel and into the earth via the ground wire. Wired properly the current should also travel back along the neutral to whatever breaker is supplying the current, causing it to trip (shut off) and preventing possible electrocution. This is called box bonding and is very important. All panels need to be bonded.

So the EGCs and Neutrals need to be connected in a main panel but not connected in a subpanel and all boxes need to be bonded. This is essential to avoid putting current where it should not be, ensuring breakers trip properly, etc. These are some of the most basic of electrical principles and yet we often find new work that does not comply with them. This is the reason amateurs should not do any electrical work without proper training and thorough knowledge of dos and don’ts.

This is a subpanel from a home that was less than 20 years old. The neutrals and EGCs are connected (bonded) when they should not be. Notice the white wires and bare copper wires are landing on the same bus bar. That’s wrong and can put current in places it’s not meant to be.

The green screw at the top is a bonding screw. It does the same thing as the bonding jumper mentioned above. It has been backed out meaning the panel is not bonded. If a wire came loose it would electrify the box and nothing would stop the current. Fires or electrocution could occur.

These are two safety defects that were done wrong at the time of construction. It’s sad to see this on newer homes but thankfully this is a simple fix in most cases. One way to fix this would be to put the white neutral wires on the left side of the panel and the copper “grounds” or EGCs on the right. The green bonding screw would be installed to bond the panel. Any jumpers connecting the neutral and ground sides would then be removed. As long as the service neutral was connecting to the neutral bus bar and EGC connecting to its bus bar, everything would be proper. The panel would be bonded and properly wired.

Call today for your home or mold inspection.